At present, there are still local outbreaks in China, and the epidemic has continuously slowed production and reduced liquidity in various regions.

The normalization of the epidemic is actually promoting the transformation and upgrading of enterprises, which can not help but ask, it is difficult for solid wood furniture enterprises to build a digital manufacturing system? Difficult! But should we transform and upgrade? The answer is yes. The main reasons are as follows:

1 The epidemic has created a labor shortage

The manufacturing industry has low profit and high cost, which makes it difficult to support the high income of employees. Moreover, the production of young workers can not be guaranteed, so the quality is unstable and the management is not systematic.

2 Markets and technology are also subtly pushing

First of all, the market, now solid wood furniture in the manufacturing of marginal profit era, the use of digital manufacturing can improve production efficiency, reduce manufacturing costs.

Then comes the technology. At present, the equipment of many domestic furniture manufacturing enterprises can be flexibly produced. The digital manufacturing of solid wood furniture can effectively shorten the delivery cycle and reduce after-sales service in the face of the increasingly strong personalized demand of the market.

3 The development transformation under the industry background

The whole house customization of panel furniture that we are familiar with has realized one-stop service. At present, it is urgent to develop the transformation and upgrading of solid wood furniture manufacturing industry to intelligent manufacturing, and it is urgent to play a role in the critical period of transformation.

4 Policy orientation is also an opportunity to move forward

In recent years, the state has given more and more support to the technological transformation, innovation and intelligent manufacturing of the manufacturing industry. The digital manufacturing of solid wood furniture is consistent with the relevant policies of the state, which is also an opportunity to build the digital manufacturing of solid wood furniture.

Therefore, the digital manufacturing of solid wood furniture relying on science and technology is a trend and a necessary way for solid wood furniture enterprises to maintain their competitive advantages. To realize such a way, the following aspects should be reflected.

1 Intelligent design

The intellectualization of furniture design is mainly reflected in the design and research and development of intelligent furniture products. The standardization of design software system is used to form standardized modules and avoid the error inaccuracy and other details problems existing in traditional drawing design.

2 Manufacturing intelligence

Traditional furniture production, labor demand is large, high density, low production efficiency, machining workshop noise, dust pollution, paint workshop harmful gas seriously exceeded, etc., all of these harm the health of workers, while affecting the production quality.

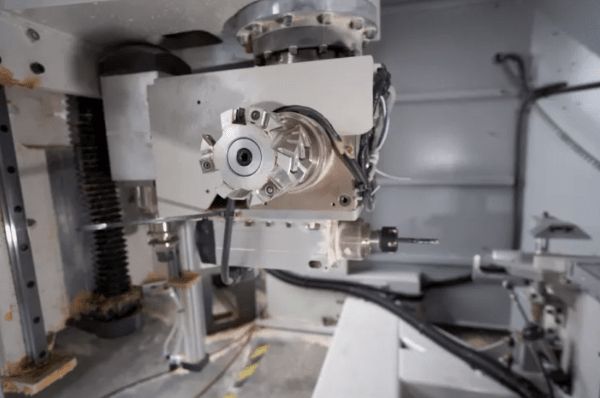

Using intelligent manufacturing to replace labor not only solves the production efficiency but also can solve the production safety and environmental protection problems. Taking the numerical control mortise and tenon in solid wood furniture production as an example, numerical control mortise and tenon machine can not only improve the production efficiency and machining accuracy, but also suitable for the processing of special-shaped mortise and complex mortise parts.

1)、Efficient production reduces input

Three stations can do the material immobility, the head movement, improve the production efficiency of 40%, effectively reduce the investment of capital.

2)、Wide processing surface and easy operation

Directional research and development of high-speed mortise and tenon processing center is a big highlight, more convenient operation, more humane, can produce 95% of the conventional mortise and tenon structure on the market.

Mortise and tenon sample

3)、Simplify production and ensure quality

The automatic, numerical control and informationized three-station tenon opening equipment solves the complex, precise, multi-variety and small-batch production problems in solid wood processing, and improves the quality and efficiency of mortise and tenon processing.

In addition, through the cloud server, cloud database, remote operation and maintenance of the workshop local database, the central control MES system, seamless docking of the production process, can provide real-time online maintenance, monitoring the production line status, collection of data to automatically generate a map, to achieve efficient, environmental protection and high quality production.

3 Intelligent management

Manufacturing enterprises production process execution management system for customized furniture enterprises mainly reflected in the real-time monitoring and management of the site, equipment maintenance and production schedule tracking.

Continuous innovation, including business model innovation, production model innovation, operation model innovation to decision-making model innovation, comprehensive intelligent management of furniture products, which to a large extent, reduce the production cost, increase enterprise income, to achieve intelligent management of enterprises.

4 Service intellectualization

Intelligent service, cloud computing technology is applied to furniture order information and customer information and other big data to achieve intelligent information management. Through data processing and analysis, it can also predict the fashion trend of furniture market, provide customers with furniture selection in real time, and achieve accurate service.

Digital production can be said to be one of the keys to the survival of furniture enterprises. Now the traditional production mode has gradually been unable to adapt to people’s fast life and national environmental protection requirements, and the digital transformation of furniture industry is imminent.