SM-2560 is a high-speed doors and windows milling, mortise and tenon machining center with directional research and development. It is more convenient and humanized to operate. It can produce various forms of mortise and tenon, core board milling, wall panel processing, floor processing, 45 degrees, 90 degrees and 135 degrees doors and windows tenon processing.

The production and processing are all modularized, no need to calculate the processing data, only need to input the material specifications and other data.

Dozens of mortise and tenon processing are merged into one equipment (continuous upgrading), which is widely used in the production and processing of furniture mortise and tenon.

The transformation of intelligent manufacturing is an inevitable trend, and it is also an important direction for the future development of the manufacturing industry. Whether it is the change in the population structure, which leads to a continuous increase in labor costs, or the rapid update of market demand, there is a need for flexibility in factories. Intelligent panel furniture production lines must be efficient, energy-saving, and agile to respond to uncertain external environmental changes.

wood door machine/door making machine SM-2560 is specially designed for processing cabinets, doors, and windows, floors, wall panels, etc. Whether it is whole-house customization, door and window enterprises, or antique processing, SM-2560 can solve your problem of fast shipping.

Door And Window SM-2560 can help you increase productivity, increase efficiency, increase yield, improve quality, save costs, and automate production.

There are many production process procedures for solid wood door panels, and the frame and core panels have different processing techniques.

Solid wood board—truncating—longitudinal solution—planing on the base plane—planing on all sides—fine cutting—tenoning—punching—milling—assembling door core board—outline milling—sanding—finishing

Solid wood board – truncation – longitudinal analysis – rough planing – matching board – glue assembly – double-sided planing – fine cutting – milling – sanding – asse

| Size: | 4400(L)*1610(W)*1740(H) |

| Material size: | 2500(L)*60(W)*60(H) |

| Milling Depth | 120mm |

| equipment weight | 2500Kg |

| Voltage/Frequency/Power | 380v / 50Hz / 21.5Kw |

| Vacuum outlet | 100*4 |

| X-axis, Y-axis moving speed | 30 rice/min |

| Z-axis moving speed | 10 rice/min |

| Repeatability | ±0.1 |

| barometric pressure | 0.5~0.8Mpa, |

| Milling spindle speed/shaft diameter | Max 12000 rpm/D30 |

| Milling spindle speed/specification | Max 9000 rpm/D35 |

| Milling spindle speed/specification | Max 18000rpm/ER25(4-16mm) |

Advantage

It combines milling shape, mortise and tenon structure processing, which reduces repetitive placing materials times, improves processing efficiency

It integrates multiple processing methods and functions, reduce the number of tooling and equipment maintenance costs

Dozens of processing technologies, without waiting and program switching, meanwhile the program is constantly upgrading and optimizing

The high strength integrated body to improve processing accuracy, meet the high precision requirements of different material processing

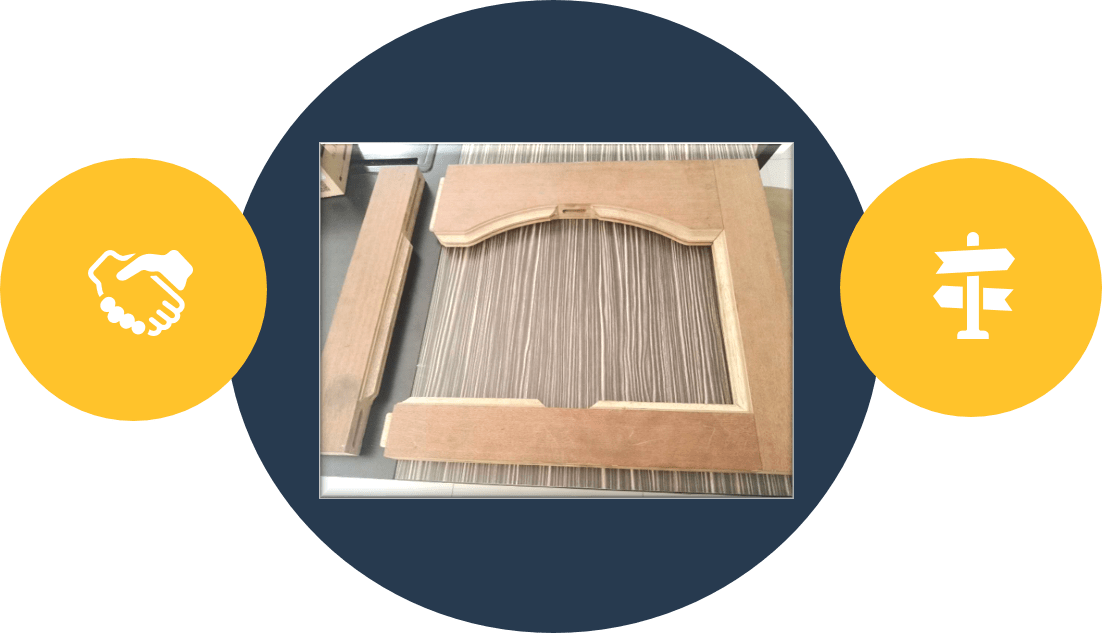

Sample

Drive the innovation of smart tenon joints and build a model of the smart industry together.

Suzhou shikainiu CNC Equipment Co., Ltd. is a high-tech enterprise in Jiangsu Province. The company inherits the traditional Chinese furniture manufacturing technology and reproduces various tenon and mortise processes through modern equipment. The main products are optimizing sawing, tenon and mortise production, door and window production.

Add:18-2 Tiandoli Road, Yangcheng Lake Town, Xiangcheng District, Suzhou, Jiangsu

request a quote